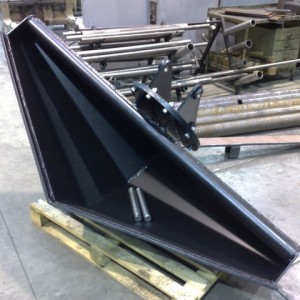

Standard loading buckets

- They are intended for front loaders, handlers, front loaders of tractors, skid steer loaders, etc.

- They are intended for the handling of standard building materials, such as sand, crushed aggregate and other materials up to a specific weight of 1.8t/m3

We manufacture loading buckets with attachment systems according to the machine type.

The dimensions and design, as well as size of the loading buckets depend on the machine type, work method, type of the handled material and customer’s requirements.

The buckets are made of high-strength steel, stressed parts are made of high-strength and abrasion resistant steel materials “HARDOX 450”.

The buckets are fitted with a basic induction-tempered bit and they can be fitted also with a welded or screwed sub-bit, configured as one whole or as a sectional system.

The buckets can be equipped with the following accessories:

- Tooth system and segments between teeth.

- Strengthening of the lower part of the bucket with the help of welded-on or screwed footing soles

- Protective collar against material overfalls into the boom area

According to the type of the loader and the material handled we will recommend you the most suitable size or appropriate modifications.